YN-C909 Libi Water-soluble Polyurethane Grouting Material

Product Introduction

YN-C909 Lidawang water-soluble polyurethane grouting material is a high-molecular grouting and leakage-stopping material chemically synthesized from polyisocyanates and polyhydroxyl polyethers. This material undergoes a chemical reaction when exposed to water, forming an elastic gel-like consolidated body, thereby achieving excellent water-stopping performance. Polyurethane grouting material is a type of grouting material used in rock and civil engineering projects for water blocking, seepage prevention, and reinforcement. It reacts immediately upon contact with water, rapidly expanding in volume to form a gel that is insoluble in water, has high strength, and is elastic. It is widely used in waterproofing and leakage stopping of underground engineering, foundation reinforcement of buildings, stabilization of complex strata, reinforcement of dam foundations and tunnels to prevent water dripping, reinforcement of broken bodies, reinforcement of subway foundations, reinforcement of bridge foundations and crack repair, water stopping and reinforcement in mine construction, and other aspects.

Product Features

-

Upon contact with water, the grout automatically disperses, emulsifies, and foams, immediately undergoing a chemical reaction to form an impermeable, elastic, gel-like consolidated body with excellent water-stopping performance.

-

The elastic gel-like consolidated body formed after the reaction has good ductility, elasticity, impermeability, and low-temperature resistance, maintaining its original shape for a long time in water.

-

After mixing with water, the grout has low viscosity and good injectability.

-

As the grout reacts with water to form an elastic consolidated substance, it simultaneously releases CO2 gas. With the aid of gas pressure, the grout can further penetrate into the gaps of the structure, allowing porous structures or strata to be completely filled and compacted. It exhibits secondary penetration characteristics.

-

The grout has excellent expansibility and high water-holding capacity, with good hydrophilicity and injectability. Additionally, the viscosity and curing speed of the grout can be adjusted according to requirements.

-

Polyurethane has strong adhesion to soil particles, forming a high-strength elastic consolidated body that prevents foundation deformation, cracking, and collapse, thereby reinforcing the foundation.

-

The viscosity and curing speed of the grout can be adjusted. The grouting equipment and process are simple, requiring minimal investment costs.

-

Oil-soluble polyurethane grouting materials consist of two components: the main grout and an accelerator. In contrast, water-soluble polyurethane grouting materials are single-component materials.

Scope of Application

- Leak sealing and sealing of cracks, expansion joints, construction joints, and structural joints in various buildings and underground concrete projects.

- Drilling wall leak sealing and reinforcement for geological drilling projects.

- Reservoir dam grouting, water tunnel crack sealing and seepage prevention, and seepage prevention and reinforcement of dam concrete cracks in water conservancy and hydropower projects.

- Reinforcement and stabilization of the roadbeds of high-rise buildings, railways, and high-grade highways.

- Water blocking in tunnels and reinforcement of fractured layers such as roofs in coal mining or other mining projects.

- Reinforcement of bridge foundations and reinforcement of bridge cracks.

- Reinforcement of deformed buildings, reinforcement of concrete structures such as water towers and water tank cracks, and prevention of subsidence.

- Soil improvement, protection of soil surfaces, and stabilization reinforcement.

Construction Method

- Inspection: Carefully inspect the leaking area and clean the dirt near the leakage site to prepare for grouting.

- Hole Layout: Drill grouting holes at the leaking location. For deep cracks, oblique holes can be drilled to cross the crack surface, with a general hole spacing of 20cm-50cm.

- Nozzle Embedding and Sealing: Embed the grouting nozzles and seal them with quick-drying cement.

- Grouting: Determine the grouting pressure and grouting volume based on the specific conditions of the leaking area. Use a leak-stopping grouting pump to inject the product into the cracks. When pure grout appears in adjacent holes, move to the adjacent hole and continue grouting under the specified pressure until no further grout can be injected (injection rate ≤ 0.01L/min), then close the valve immediately. (The typical grouting pressure is 0.3Mpa).

- After 72 hours, check the leaking area for any water seepage. If there is no seepage, break off the grouting nozzles and seal and smooth the base surface with quick-drying cement.

Precautions

- During construction, please wear protective equipment (such as gloves and goggles) to avoid direct skin contact. If contaminated, rinse immediately with plenty of water.

- This product is a solvent-based material. Please ensure proper ventilation and keep away from fire sources during construction. Do not use open flames near the construction area until the material is fully cured.

- After using the machine, clean it thoroughly with a cleaning agent immediately.

Product Storage

During transportation, avoid collision, direct sunlight, rain, and fireworks. Store in a cool and dry place.

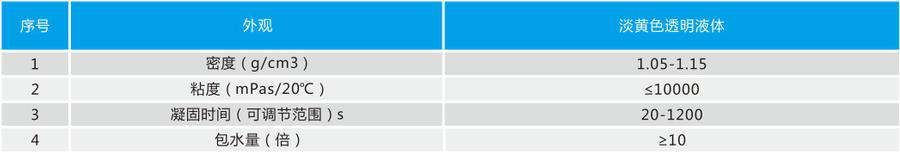

Technical Indicators

Executive standard: JC/T 2041-2010