Product Overview

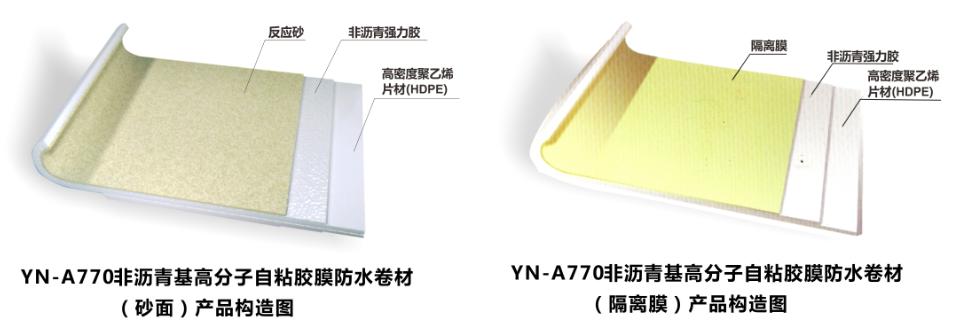

YN-A770 Non-Asphalt-Based Polymer Self-Adhesive Waterproof Membrane is a multi-layer composite waterproof material, comprising a layer of high-density polyethylene (HDPE) sheet, a layer of powerful adhesive capable of bonding with the HDPE sheet and reactive sand, and a layer of specially treated reactive sand particles.

This waterproof membrane achieves high-strength bonding with cast-in-situ concrete through chemical crosslinking and physical anchoring, effectively preventing moisture infiltration into the gaps between the waterproof membrane and the structure, i.e., preventing "water migration." Due to the air-laid installation with the cushion layer, it avoids tensile damage to the waterproof layer caused by cushion damage. This material exhibits excellent mechanical puncture and cutting resistance, allowing for the direct binding of steel reinforcement and pouring of concrete on the surface of the waterproof layer without the need for a protective layer, thereby saving material costs, labor costs, and construction time. The material has excellent weather resistance, with a service life of up to 50-70 years in underground applications.

Product Characteristics

-

Anti-Settlement and Anti-Cracking

Due to the pre-laid inverted-adhesive construction method, the waterproof membrane is laid on the substrate without bonding, ensuring that even if the cushion layer undergoes settlement or deformation, its waterproof performance remains unaffected. -

Skin-Like Structure Prevents Water Migration

The waterproof membrane installed using the pre-laid inverted-adhesive method undergoes a chemical reaction with the subsequently poured concrete, forming a tightly bonded skin-like waterproof layer. Even if the membrane is locally punctured or damaged, water migration will not occur. -

Unique Formula for Comprehensive Waterproofing

Composed of specially formulated non-asphalt reactive adhesive, special reactive sand, and polymer sheet material, the membrane combines the high tensile strength and good elongation properties of polymer membranes with the good adhesion and ease of installation of self-adhesive membranes. -

Impact Resistance and Puncture Resistance

Plastic polymer sheet material exhibits excellent impact resistance and resistance to puncture, capable of bearing the construction loads directly applied to it and the impact of subsequently poured concrete. It is particularly suitable for the construction of subsequently poured concrete and secondary lining. -

Mold and Mildew Resistance with a Durability of 70 Years

Compared to traditional materials, it exhibits superior mold and mildew resistance, as well as excellent acid and alkali resistance. Testing and theoretical calculations indicate that its service life in underground engineering and traffic tunnels can exceed 70 years. -

Low Substrate Requirements and Fast Construction Schedule

The pre-laid construction method requires no substrate leveling and is unaffected by weather or substrate moisture, making it ideal for construction in rainy seasons and projects with tight schedules. -

Cold Installation, No Heating Required, Fast Construction

Using special self-adhesive tape for lap seams saves time and effort compared to traditional hot-air welding, providing more flexible and efficient construction. -

Eco-Friendly and Green

The construction process requires no substrate preparation, solvents, fuels, or welding, reducing environmental pollution, fire hazards, and energy consumption.

Specification and Model

Thickness: 1.2mm/1.5mm

Length: 25m/20m/15m

Width: 1.0m - 2.0m

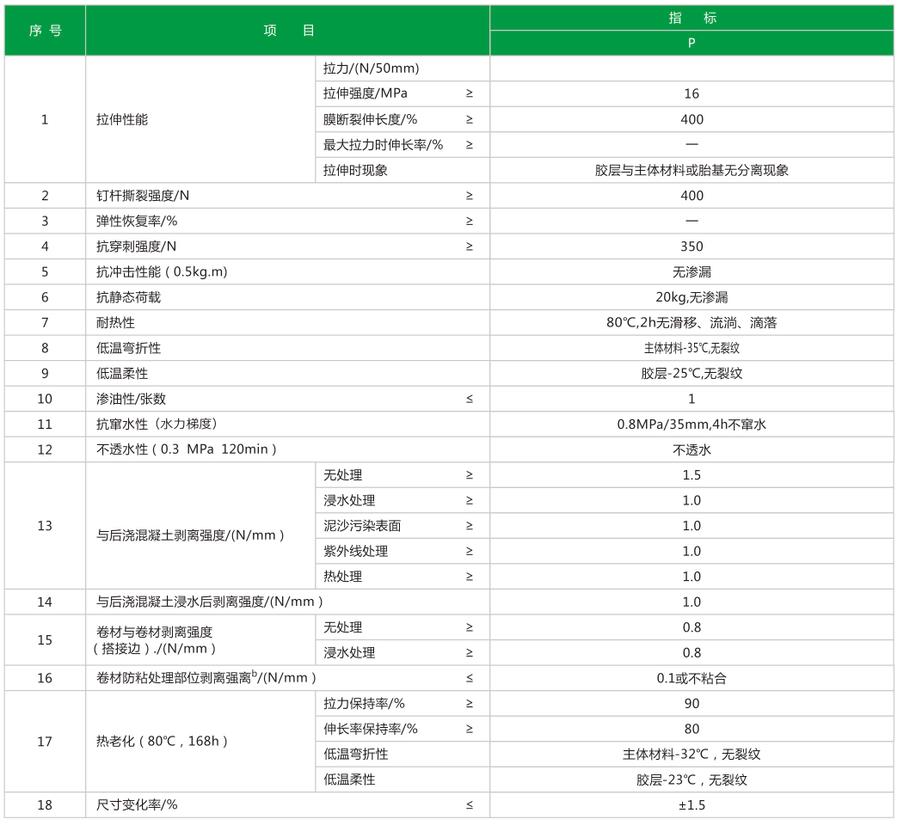

Technical Specifications

Execution Standard: GB/T 23457-2017 (Pre-laid Type P)